Kolene Corporation provides foundries worldwide with specific Kastech® molten salt bath casting cleaning processes. Capable of removing 100% of virtually any contaminant from ferrous and select non-ferrous castings (including aluminum), Kastech processes are fast, safe, and more efficient than mechanical methods. Intricate or deep internal passages are cleaned as thoroughly as exposed surfaces.

Kolene Corporation provides foundries worldwide with specific Kastech® molten salt bath casting cleaning processes. Capable of removing 100% of virtually any contaminant from ferrous and select non-ferrous castings (including aluminum), Kastech processes are fast, safe, and more efficient than mechanical methods. Intricate or deep internal passages are cleaned as thoroughly as exposed surfaces.

Kastech processes allow foundries to tailor their cleaning operations to the type of ferrous and non-ferrous castings produced and the required production throughput. In addition, Kastech processes do not attack substrate materials and they do not affect dimension integrity.

Kolene supplies custom-designed Kastech process equipment with options for automation, material handling, post-treatment, and by-product removal.

Kolene also offers casting cleaning services at our Detroit headquarters. For more information, please visit Commercial Processing.

For more detailed information, please make a selection from the options below:

Cast Iron / Sand

The Kolene Kastech® Electrolytic™ process is one of the fastest, most efficient and cost-effective methods for cleaning ferrous castings.

Aluminum Investment

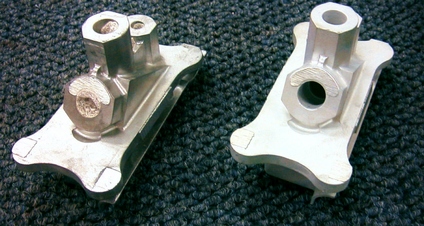

With the introduction of Kolene's Kastech® AL750 process for leaching ceramics from aluminum investment castings, foundries now have the potential to produce more complex and sophisticated aluminum castings.

Investment

Kolene Corporation offers investment casting manufacturers cost-effective, high-performance methods for cleaning both ferrous and select non-ferrous castings, including aluminum.