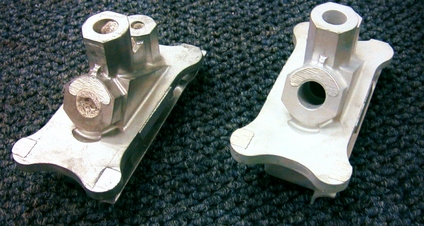

With the introduction of the Kolene® Kastech® AL750 process for leaching ceramics from aluminum investment castings, foundries now have the potential to produce more complex and sophisticated aluminum castings. Utilizing molten salt to leach silica-based shell and core residues, delicate castings can now be produced that previously could not be cleaned by mechanical methods alone.

With the introduction of the Kolene® Kastech® AL750 process for leaching ceramics from aluminum investment castings, foundries now have the potential to produce more complex and sophisticated aluminum castings. Utilizing molten salt to leach silica-based shell and core residues, delicate castings can now be produced that previously could not be cleaned by mechanical methods alone.

Cleaning your aluminum castings with AL750 produces potential benefits on a number of different levels:

- allows for more complex castings with respect to internal passages

- multiple castings can be processed at one time since salt bath cleaning is an immersion process

- provides a valuable new tool to optimize quality, throughput, and efficiency

- a safer and more gentle option for ceramic removal from extremely fragile castings

Kolene also offers Kastech AL750 aluminum casting cleaning services at our Detroit headquarters. For more information, please visit Commercial Processing.