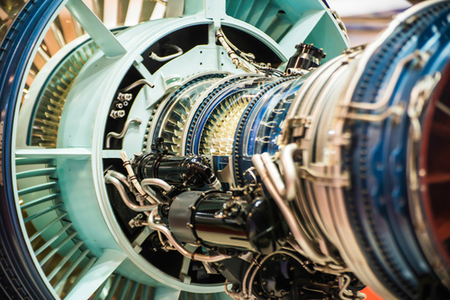

Original equipment manufacturers and maintenance, repair, and overhaul facilities both benefit from Kolene® molten salt bath processes for cleaning jet engine components.

Original equipment manufacturers and maintenance, repair, and overhaul facilities both benefit from Kolene® molten salt bath processes for cleaning jet engine components.

Whether you need to remove forming lubricants or service scales, Kolene cleaning processes provide speed, thoroughness, and repeatability unmatched by other processes. Widely specified by OEMs for MRO activities, process equipment and chemicals are available world-wide. Systems are sized for your unique needs, and can include integrated material handling systems and auxiliary wet stages as needed.

Whether for commercial or military applications, Kolene provides cleaning you can trust.

Benefits of utilizing Kolene metal cleaning and conditioning include:

- surface scale and oxide conditioning on a wide variety of alloys including stainless steels, superalloys, titanium, and refractory metals such as tungsten and molybdenum

- removal of hot forming lubricants including molten glass, moly disulfide, graphite, and boron nitride

- conversion of tenacious service-induced oxidation from blades, buckets, hot sections, vitreous deposits from sand ingestion, and sulfidation

- removal of plasma coatings – including carbides, metallics, and ceramics – in preparation for recoating and renewal

- rapid and complete removal of surface carbon, sulfidation, scale, and other surface contaminants from hot section components

- fast, complete removal of all organics including CARC (Chemical Agent Resistant Coating), epoxies, polyurethanes, electrocoats, etc.