Kolene processes will remove 100% of all paints and coatings from your racks and fixtures in seconds, with no ash residue or secondary cleaning required. Coating removal should be considered an integral part of the overall finishing operation – not an afterthought. Proper stripping techniques have a positive impact on overall line productivity, quality, and yield.

Kolene processes will remove 100% of all paints and coatings from your racks and fixtures in seconds, with no ash residue or secondary cleaning required. Coating removal should be considered an integral part of the overall finishing operation – not an afterthought. Proper stripping techniques have a positive impact on overall line productivity, quality, and yield.

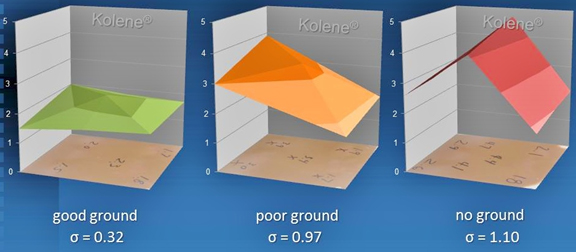

Maintenance stripping keeps racks, hooks, and fixtures clean to provide good grounding and minimize any dirt or debris on parts. Clean racks promote uniform film build, good transfer efficiency, and high part yield off your coating line.

Kolene molten salt bath stripping processes remove virtually all organic coatings, including:

- liquid paints and powder coatings

- polyesters and nylons

- epoxies and hybrids

- chlorinated and fluorinated polymers

- CARC (Chemical Agent Resistant Coating)

Process benefits include:

- 100% clean racks, fixtures, and tooling — no secondary cleaning required

- no dirt contamination from poorly cleaned racks = fewer paint defects

- improved finish quality

- fewer rejects

- no rack damage

- better transfer efficiency

- fast rack turnaround

- increased film build uniformity

Kolene process equipment is custom engineered for your specific requirements, allowing for easy installation and integration into your facility, whether it’s a retrofit or new installation.