Most Kolene® cleaning processes operate at elevated temperatures and require specialized equipment for proper operation and safety. Kolene has been designing and engineering purpose-specific process equipment since the company’s start in 1939. It continues today with an emphasis on environmental, health, and safety, with energy efficiency and ease of use following close behind.

Most Kolene® cleaning processes operate at elevated temperatures and require specialized equipment for proper operation and safety. Kolene has been designing and engineering purpose-specific process equipment since the company’s start in 1939. It continues today with an emphasis on environmental, health, and safety, with energy efficiency and ease of use following close behind.

The design process begins with in-depth discussions with our customers to determine what will be needed to provide a system that performs as desired. Some of the more important questions include:

- What are the objectives of the process?

- How many / how large are the parts to be cleaned?

- What materials are involved?

- Will the system be manually operated or fully automated?

- Does the customer want a minimal configuration or complete process line?

Once we have these questions answered, our engineering group works with our applications lab and sales personnel to specify a system based on process parameters developed by Kolene. The end result is a customized process solution for each customer’s unique application.

With more than 75 years of experience, we have produced a wide variety of cleaning systems. Many are similar in design, but most end up with features unique to each customer. Below please see some examples of our salt bath cleaning units. Please remember that these are only a few examples of what we have produced, and that our solution for your cleaning application will be designed with your unique requirements in mind.

THERMOCHEMICAL CLEANING SYSTEMS

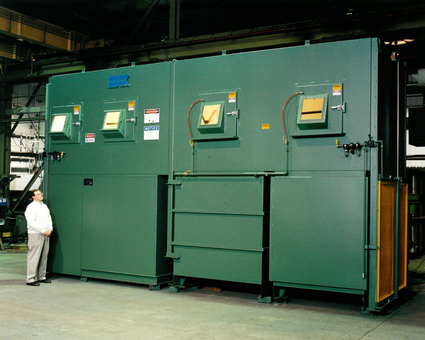

BATCH SYSTEMS

Batch cleaning units are designed to process discreet loads or batches of parts. These units can be placed under an existing rail and hoist or we can supply various types of manual or automated handling systems. Floor, roof, or unit-supported handling systems are available.

Molten Salt (thermochemical) Cleaning Systems

For molten salt (thermochemical) systems, a minimal cleaning system configuration consists of the molten salt cleaning furnace, a by-product removal zone, and at least one water rinse tank. Ventilation of the system is also included. Optional stations include hot water rinses, brightening or neutralizing stations, and additional salt bath furnaces as required.

Unit size is determined by the size and volume of parts to be cleaned.

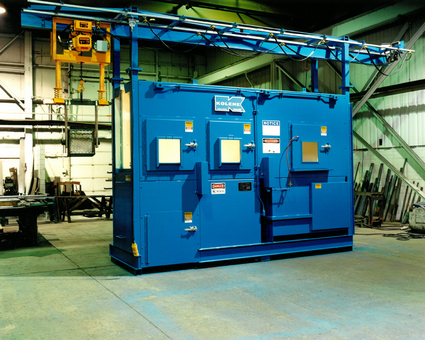

Unitized Systems

Unitized systems are typically smaller batch systems that can be pre-assembled before shipment to speed up the on-site installation at your location. All components – molten salt bath, water rinse tank(s), by-product removal zone, etc. – are mounted on a common I-beam base. To the extent possible, all componentry are pre-piped and pre-wired to minimize on-site installation burden.

Unitized systems are typically smaller batch systems that can be pre-assembled before shipment to speed up the on-site installation at your location. All components – molten salt bath, water rinse tank(s), by-product removal zone, etc. – are mounted on a common I-beam base. To the extent possible, all componentry are pre-piped and pre-wired to minimize on-site installation burden.

For larger systems, we can also provide modular systems that can be readily field-joined on your plant floor.

Electrolytic™ Salt Baths

Our Electrolytic™ molten salt baths are used exclusively for direct current activation of molten salt chemistries. These systems are commonly used for sand, graphite, and scale removal of iron sand castings. The electrolytic activation is also used for conditioning and/or removing tenacious metallic and ceramic compounds from high-value components for rebuild and remanufacturing.

Our Electrolytic™ molten salt baths are used exclusively for direct current activation of molten salt chemistries. These systems are commonly used for sand, graphite, and scale removal of iron sand castings. The electrolytic activation is also used for conditioning and/or removing tenacious metallic and ceramic compounds from high-value components for rebuild and remanufacturing.

Unique design features of these systems include sacrificial wear surfaces in the operating bath that can be readily replaced as required, increasing the service life of the furnace.

Electrolytic salt baths are variants of Batch and Unitized salt bath designs.

INTEGRATED LINES

Kontinuous™ Paint Stripping Systems

Kontinuous paint stripping systems are custom-designed to install in your paint and powder coating conveyor lines. They are located after your curing oven and rack unload, and before your unpainted parts loading station. Units are designed to provide you with stripped racks every pass through the finishing line – and at normal line speeds. This provides excellent grounding and unequalled coating build uniformity, without the need for spare racks or the labor required for frequent rack changes.

Kontinuous paint stripping systems are custom-designed to install in your paint and powder coating conveyor lines. They are located after your curing oven and rack unload, and before your unpainted parts loading station. Units are designed to provide you with stripped racks every pass through the finishing line – and at normal line speeds. This provides excellent grounding and unequalled coating build uniformity, without the need for spare racks or the labor required for frequent rack changes.

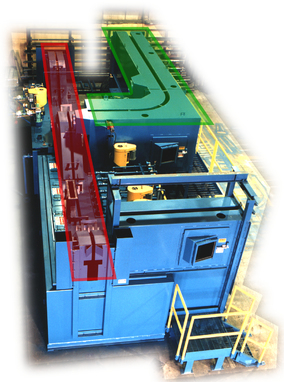

Kontinuous™ Plus Paint Stripping Systems

At the same time that racks and hooks are being stripped through the Kontinuous system’s dedicated pass-line (red zone), a second independent pass-line lets you strip reject parts. With a manually-operated hoist the “Plus” option (blue zone) allows you use the same salt bath that strips your hooks and racks. With its own water rinse tank, the manual stripping operation is completely independent of the in-line maintenance stripping activity.

At the same time that racks and hooks are being stripped through the Kontinuous system’s dedicated pass-line (red zone), a second independent pass-line lets you strip reject parts. With a manually-operated hoist the “Plus” option (blue zone) allows you use the same salt bath that strips your hooks and racks. With its own water rinse tank, the manual stripping operation is completely independent of the in-line maintenance stripping activity.

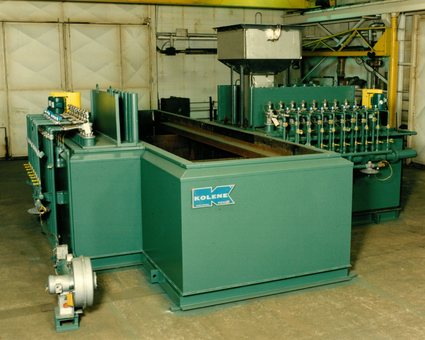

Metal Descaling Systems

Kolene custom engineers molten salt scale conditioning systems for stainless steels, nickel alloys, titanium, and select refractory alloys such as tungsten and molybdenum. Unique chemical scale conversion results in residual surface oxides that are easy to pickle, which results in brighter, more uniform products after pickling. Unnecessary metal loss is kept to a minimum. The physical shape of the products dictates the equipment layout:

Kolene custom engineers molten salt scale conditioning systems for stainless steels, nickel alloys, titanium, and select refractory alloys such as tungsten and molybdenum. Unique chemical scale conversion results in residual surface oxides that are easy to pickle, which results in brighter, more uniform products after pickling. Unnecessary metal loss is kept to a minimum. The physical shape of the products dictates the equipment layout:

For Continuous Anneal and Pickle (CAP) lines for strip, Kolene designs systems that are installed after the annealing furnace and jet cooler. Strip passes under a dunker roll to immerse the strip into the salt, where only a few seconds are required to properly condition the scale. It then immediately passes over a carry-out roll and travels to an immersion rinse tank where any conditioning salt residues are removed.

If you produce Tubing, Pipe, Profiles, Shapes, or Wire, our systems are rated based on your tons/hour throughput needs. Overall lengths or coil diameters are carefully considered in our engineering specifications. Units with usable work zone lengths of 50 feet or more are commonplace, and throughput capacities of more than 7 tons of metal per hour can be accommodated. Due to thicker, more tenacious production scales formed on these shapes, process cycle times in the bath typically run several minutes.

If you produce Tubing, Pipe, Profiles, Shapes, or Wire, our systems are rated based on your tons/hour throughput needs. Overall lengths or coil diameters are carefully considered in our engineering specifications. Units with usable work zone lengths of 50 feet or more are commonplace, and throughput capacities of more than 7 tons of metal per hour can be accommodated. Due to thicker, more tenacious production scales formed on these shapes, process cycle times in the bath typically run several minutes.

BY-PRODUCT MANAGEMENT SYSTEMS

Sludge Management System

Our SMS™ (Sludge Management System) was developed to offer an alternative processing method for the reaction products that are formed in our processes. As various contaminants are added to the bath – sand, investment ceramics, metal oxides, paints, etc. – and react with the chemicals, by-products (sludge) are formed and settle to the bottom of the bath. Once removed, they must either be sent off-site or managed internally. The SMS system safely dissolves the sludge and allows on-site management of the material.

Our SMS™ (Sludge Management System) was developed to offer an alternative processing method for the reaction products that are formed in our processes. As various contaminants are added to the bath – sand, investment ceramics, metal oxides, paints, etc. – and react with the chemicals, by-products (sludge) are formed and settle to the bottom of the bath. Once removed, they must either be sent off-site or managed internally. The SMS system safely dissolves the sludge and allows on-site management of the material.

RECOVER® REJECT PART STRIPPING EQUIPMENT

Recover® Equipment

Recover is a patented organic fluid used to strip reject or defective coatings from a wide variety of components. For best results and process life, Kolene has developed unique process equipment to safely and efficiently heat the solution to its operating temperature of about 300°F - 325°F. Once stripped, the parts are cooled and rinsed in an adjacent water tank.

Recover is a patented organic fluid used to strip reject or defective coatings from a wide variety of components. For best results and process life, Kolene has developed unique process equipment to safely and efficiently heat the solution to its operating temperature of about 300°F - 325°F. Once stripped, the parts are cooled and rinsed in an adjacent water tank.